The sensor faucet is based on the principle of infrared reflection. When the human hand is placed in the infrared area of the faucet, the infrared light emitted by the infrared transmitting tube is reflected to the infrared receiving tube due to the cover of the human hand, and the signal processed by the microcomputer in the integrated circuit is sent to the pulse solenoid valve. After the solenoid valve receives the signal, it opens the spool according to the specified instructions to control the water from the faucet; when the hand leaves the infrared sensing range, the solenoid valve does not receive the signal, and the solenoid valve spool is reset by the internal spring to control the faucet to close the water. In addition, the induction faucet also has an induction water-saving faucet. It is a newly invented high-tech product widely used in high-end places such as hotels, guesthouses, and office buildings. A responsibility, with the development of induction sanitary ware, induction water-saving faucets have been widely used.

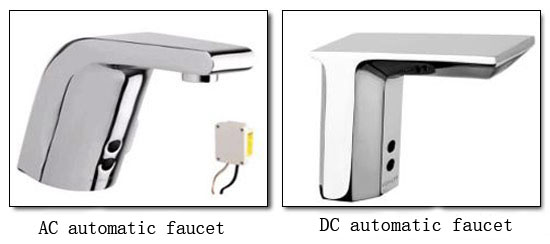

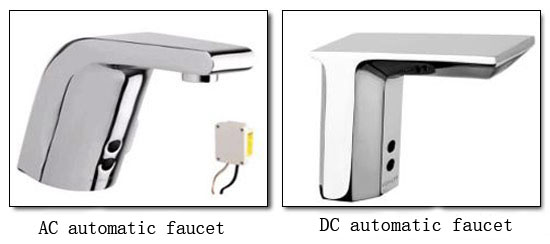

AC power supply or DC power supply, using infrared sensor, water enters the sensing area, and the water stops when leaving the sensing area. The water switch is automatically completed by the sensor without touching the faucet, which can effectively avoid bacterial cross-infection. This machine adopts microcomputer control, determines the best sensing distance according to the shape of the basin, without manual adjustment, and also has a 1-minute overtime flushing and water stop function to avoid the waste of water resources caused by the sensing of foreign objects for a long period of time. The DC power supply uses alkaline dry batteries (6V, 3V, 4.5V), built-in filters to prevent impurities from entering the solenoid valve, easy to clean, beautiful appearance, firm structure, suitable for crowded places.

Use function

Since the induction faucet does not require direct contact with the human body, it can effectively prevent bacterial cross-infection; it has the function of watering when you reach out and shutting off when you leave, which effectively saves water by more than 30%. It is especially suitable for areas with severe water shortages in our country. Nowadays, induction faucets are widely used in public places such as train stations, bus stations, airports, hospitals, etc. with high traffic.

Inductive faucets can be divided into the following types in applications:

1. Public sensor faucet---it has the function of sensing the water out of the signal and stopping the water when the signal disappears. It will automatically stop the water for a certain period of time, which is suitable for most public places.

2. Medical sensor faucet---it senses the signal to flow out, and then senses the signal to stop the water. It will automatically stop the water after a certain period of time. It is suitable for hospital operating rooms and nurses to wash hands.

3. Household sensor faucet---In addition to sensing the signal to produce water, the water will stop when the signal disappears, and the water will stop automatically for a certain period of time overtime. It also has a long-term water discharge and washing function, which is suitable for home use.

Visible sensor faucet, because the sensor faucet is an infrared reflective receiving electronic solenoid valve switch, it distinguishes obstructions instead of infrared signals. If there is no overtime, the water protection faucet will flow for a long time and waste water resources when it encounters a fixed obstruction. The overtime water cut protection time is generally set to 20-60 seconds.

The main faults and maintenance methods are as follows:

1. No water from the sensor faucet: First, determine whether the power supply is normal. The main domestic power supply methods are AC 220V transforming into 12V and 6V; DC 6V (No. 7 or No. 5 alkaline batteries) and DC 3V (two pieces of seven) No. or No. 5 alkaline battery), use your hand to block the infrared window to observe whether there is an indicator light. The infrared window of some induction faucet brands is controlled by a single-chip microcomputer. The power indicator light is in the water control part (installed under the basin). If there is a reaction, it is preliminarily judged that the sensing part is faulty, and the infrared probe can be replaced. Here, it is recommended that users who cannot judge the fault. If there are other normal sensing faucets, the troubleshooting method can be used, and the infrared part of the plug should be plugged into the faulty first. For the water control part of the faucet, it is easy to judge whether the induction part is faulty or the solenoid valve of the water control part is faulty. At the same time, pay attention to whether all the plugs have no possibility of bad contact or damp.

2. The sensor faucet can't shut off the water: remove foreign objects in front of the sensor window (the principle of the sensor is that as long as there is an object within the infrared sensor distance, the machine will respond) and the indicator light is normal, check whether the water inlet filter of the water control part If there is clogged by sand or other debris, please clean it; if the fault is not resolved, please disassemble the solenoid valve, clean the valve core, spring, diaphragm, etc. of the coil and reinstall it as it is, if the water still cannot be shut off It means that the solenoid valve is broken, just replace the part of the new solenoid valve. There is an empirical talk here. If you can’t shut off the water, if you find that the amount of water becomes larger after sensing it with your hand, you can’t shut off the water even after you leave your hand, but the water output is smaller than it was in use. This shows that the solenoid valve is not malfunctioning. , You only need to clean the inside of the solenoid valve according to the above method and it can be used normally.

3. The amount of water coming out of the induction faucet is small: on the one hand, check whether the water pressure and the flow of the pipeline itself are small, on the other hand, check whether the filter at the water inlet end of the water control part is blocked by impurities, and on the other hand, consider that the pipelines now use PPR. During the construction of the project, hot melt is used for the pipe joints, and it is not ruled out that excessive heat melt will deform the pipe and reduce the amount of water passing through the pipe.

If you have interest in sensor faucets please kindly contact with D&S Faucets Company,we will provide the best quality and good service for you.