The production process of faucets

August 04 , 2021

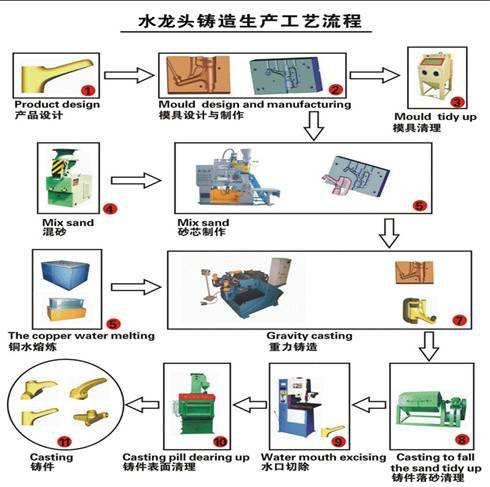

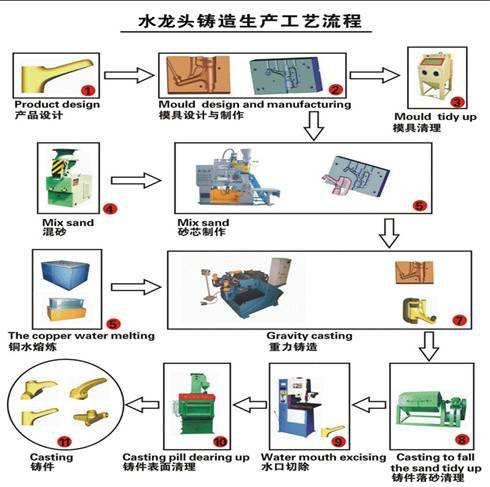

1. Traditional faucets are made of brass, and the production process as follows: copper ingot→dissolving→casting→cleaning after casting→casting inspection→machining→tolerance inspection→grinding→surface inspection→plating→plating inspection→assembly→testing Pressure→finished product inspection→packaging→factory. There are total of 16 processes, and each process is strictly controlled to achieve quality assurance. The faucet production process of other materials usually similar to the above process, except the material is different.

2. The faucet manufacturing process includes four categories: sand foundry casting, manual metal mold casting, gravity pouring machine and low pressure casting. Most of the low-end faucets on the market are manufactured using sand mold casting, that is, sand foundry casting. The inner structure of the faucet cast by this production process is sparse, and it is easy to form trachoma and pores, and the quality can't guaranteed. High quality faucets generally use gravity casting, which has a compact internal structure, and the quality also much better than sand casting one. In addition, the more advanced manufacturing process of the faucet is die-casting, which is a one-time pressure grinding molding.

3. After the faucet is cast, it must be machined, milled, planed, grinded, bored and other types of machining by various machine tools to achieve accuracy. There are also an important link in production, which is inspection, and each link is inspected strictly in accordance with the standard to ensure the quality of the product.