How to install the angle valve

Mar 10, 2022

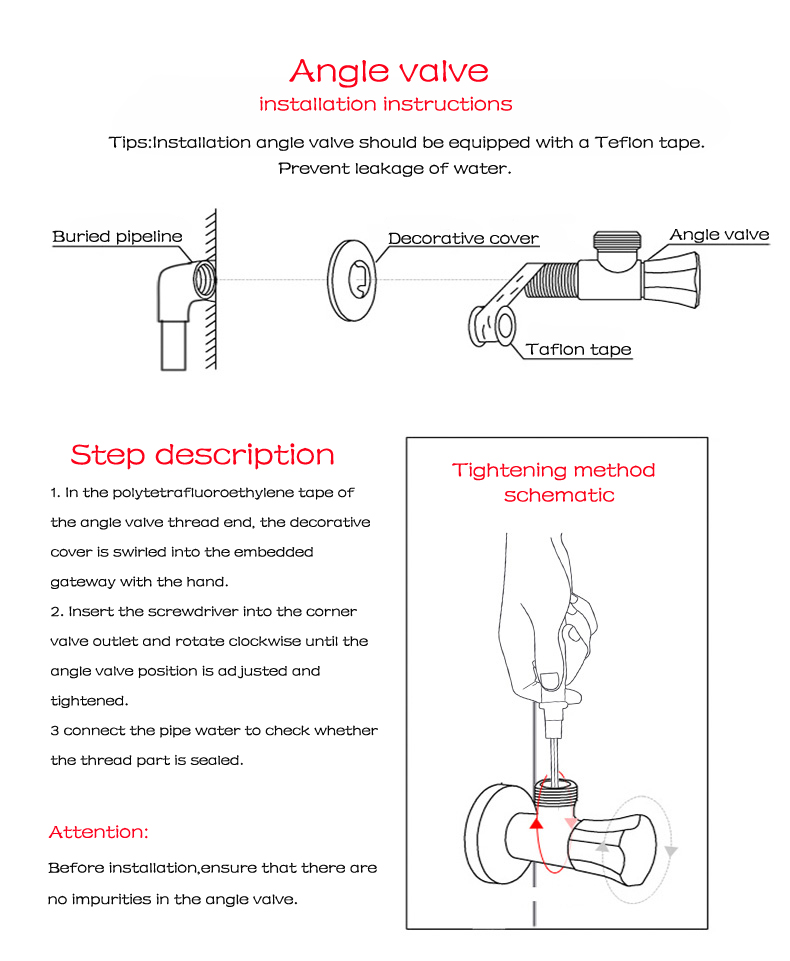

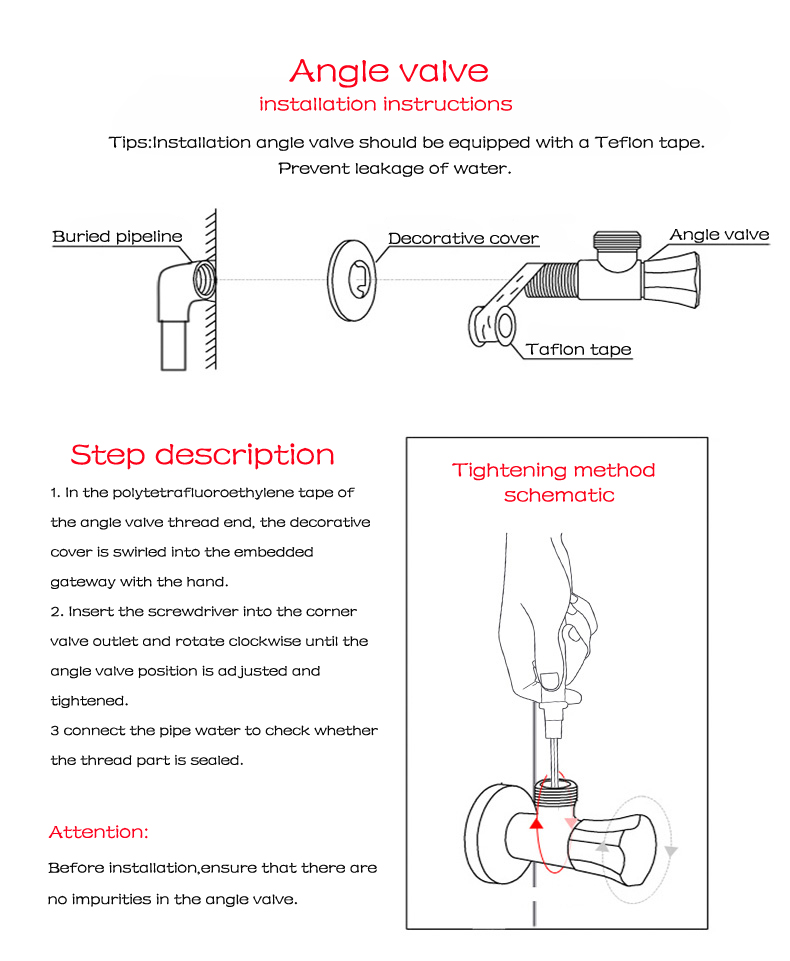

1. Before installation, it should be confirmed that there are no blisters on the surface of the product, the wall thickness of the threaded pipe is uniform, and the switch can be rotated flexibly. Before installation, the water pipe should be dredged with water once to confirm that there is no garbage and residue in the water pipe, so as not to affect the water flow.

2. Pay attention to the winding direction. Take the angle valve as an example. When the angle valve is screwed into the inner thread of the wall, it rotates clockwise to the right. Then the direction of wrapping the remaining tape on the angle valve is counterclockwise to the left. Winding, so that when the angle valve is twisted, it will be tightened more and more tightly, and it will not loosen.

3. Tighten the raw material tape when wrapping, so that the raw material tape is tightly attached to the thread, try to be as tight as possible, and do not wrap it loosely.

4. There is no hard and fast rule for "several layers" of winding, which can be tightened without leakage. However, according to experience, it is usually necessary to wind more than ten times to ensure the sealing effect.

5. When screwing the thread, don't screw it to the dead end. Use a little bit of strength. You don't have to screw it until it can't be screwed. It only needs to feel strong when screwing. Also pay attention to the depth of the screw in.

Angle valve installation precautions

1. When installing the angle valve faucet, the place where the raw material tape should be wrapped is less: I feel that it is almost enough to wrap it three or five times, and the result is always leaking.

2. When installing the angle valve faucet, wrap the raw material tape violently at the place where the raw material tape should not be wrapped: the place where the wire is connected to the hose, the two ends of the shower hose, etc., the more it is wrapped, the more water will leak.

3. The leak test was not careful: it didn't leak at the time, but it should be observed several times after that. The water is fine, but the gas should pay special attention. The gas pipeline should be brushed with soapy water on the connecting parts and joints, and the foaming should be found in time. deal with.

4. The hose (braided hose and corrugated hose) is unnaturally stressed and unnaturally bent: the hose joint cannot be bent within 5 cm from the joint, cannot be beaten to death, cannot be under constant stress, etc., under these morbid conditions Hose life will be greatly reduced.

If you have interest in angle valve please kindly contact with D&S Faucets Company,we will provide the best quality and good service for you.